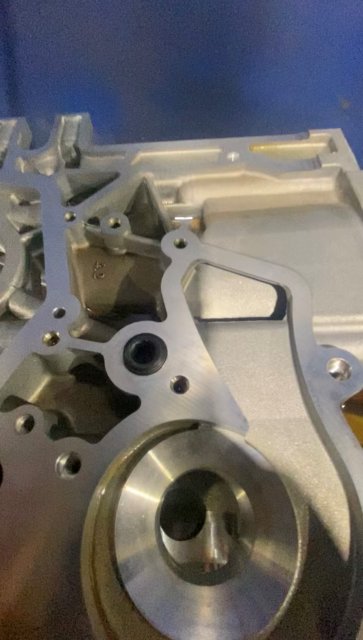

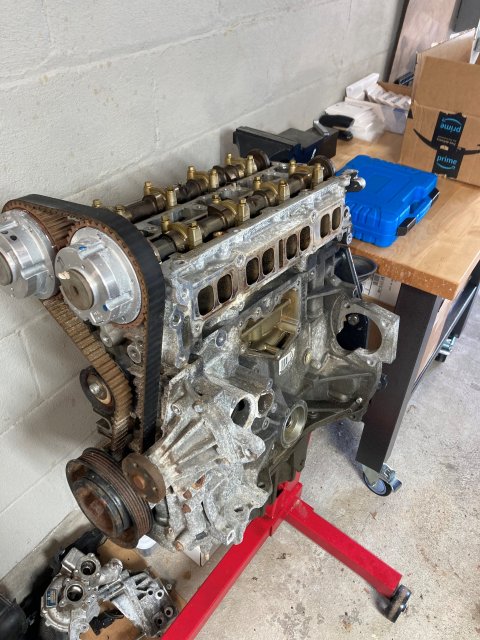

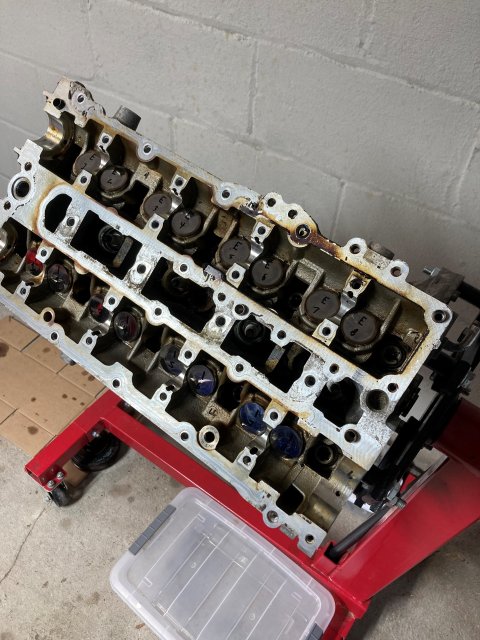

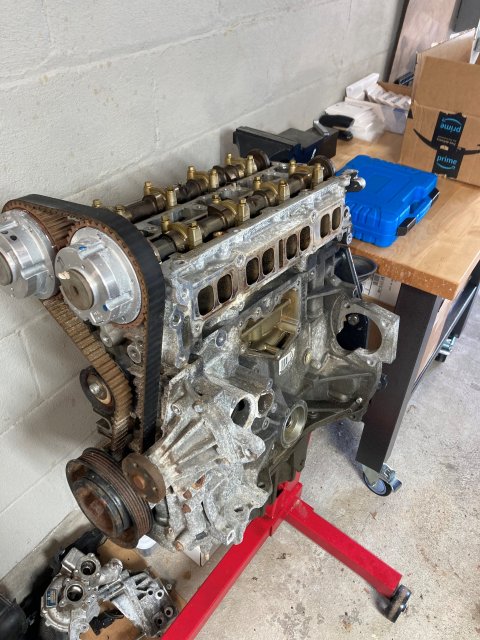

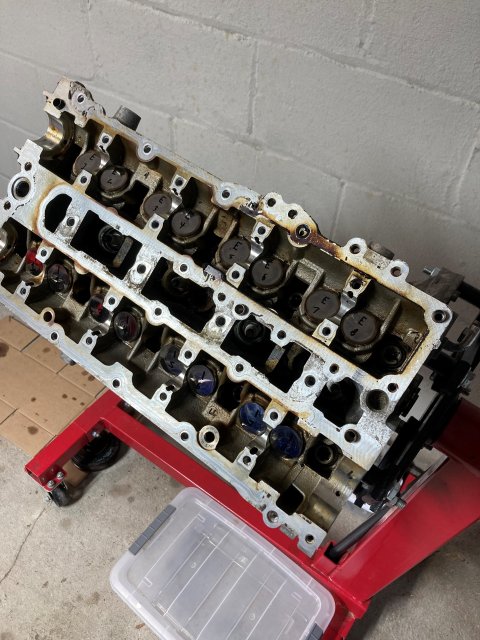

I'm starting this thread to track the progression of this build, and to share any information I learn along the way. I started with a 2015 Escape 1.6L engine with 120,xxx miles for roughly $1,500 delivered. Over the last few months (I know, I have been slacking on posting), I have torn down this engine to the bare block. I will be sending out the block for a CSS, and will be boring the cylinders .5mm up to 79.5mm. I also have another trick up my sleeve, but will discuss that when I get there. I know these sleeves are paper thin, so I am expecting to push the limits with this engine, and go sleeved on the next engine.

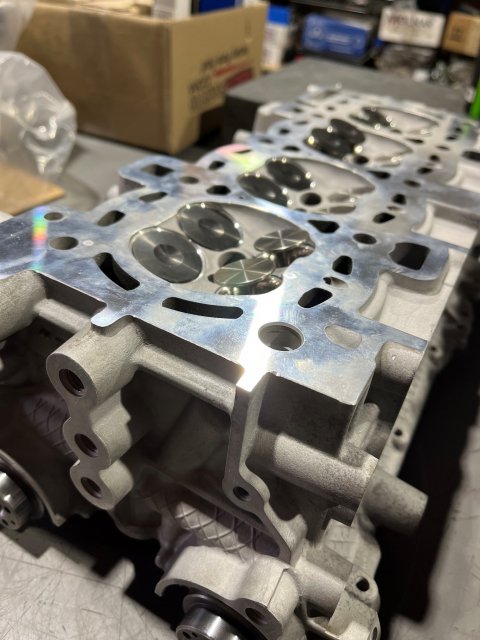

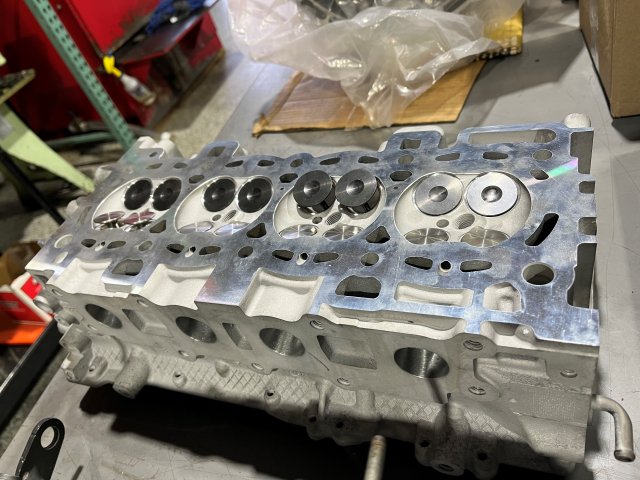

I already have most of the bottom end parts planned out (or purchased), but the head is still untouched. I want to do Stage 2 cams, valves, springs and some mild port work, but again, I'll discuss that when I get there. I purchased a brand new Ford crank, timing gear and crank pulley and sent them to Speed Perf6rmanc3 to be keyed. Those should be coming back any day.

Bottom end build is as follows:

CSS block

Wiseco pistons

K1 rods

All ARP hardware

King Race bearings

OEM oil pump

oem crank (keyed)

Here are some photos of the progress and where it stands now.

I already have most of the bottom end parts planned out (or purchased), but the head is still untouched. I want to do Stage 2 cams, valves, springs and some mild port work, but again, I'll discuss that when I get there. I purchased a brand new Ford crank, timing gear and crank pulley and sent them to Speed Perf6rmanc3 to be keyed. Those should be coming back any day.

Bottom end build is as follows:

CSS block

Wiseco pistons

K1 rods

All ARP hardware

King Race bearings

OEM oil pump

oem crank (keyed)

Here are some photos of the progress and where it stands now.

Last edited: