Hello everyone,

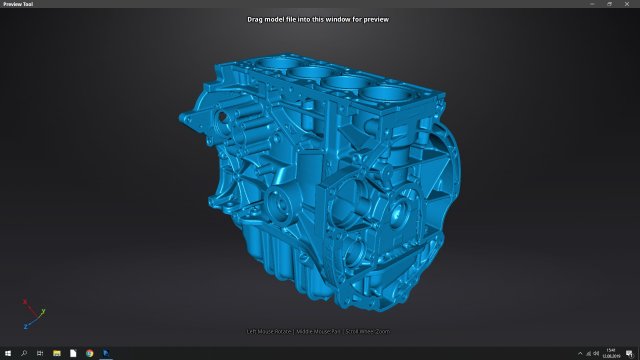

Although I am on the other side of the globe, I found my way here through some searches concerning 1.6 Ecoboost engine builds. Long story short, I am now posting our rallycar build here. The team we are operating is named Kaur Motorsport.

As to this date, the car is only using the engine and the body from ST180- I apologize if that is not enough of ST180 parts to qualify to this forum(or for your personal taste). But it seemed to me it is the best place to find likely-minded people where 1.6 Ecoboost is involved and I could also accumulate more knowledge myself through some discussions.

I will start with the body and what has been done:

1. Completely stripping the body and removing unnecessary components.

2. Modifications to the body to install R5 bodykit and custom suspension. Container for homologated ATL fuel tank.

3. Installing a TIG-welded CrMo rollcage kit with FIA approved homologation. Custom steering column attachments to move seating position towards the rear of the car.

4. New tunnel to accommodate the propshaft.

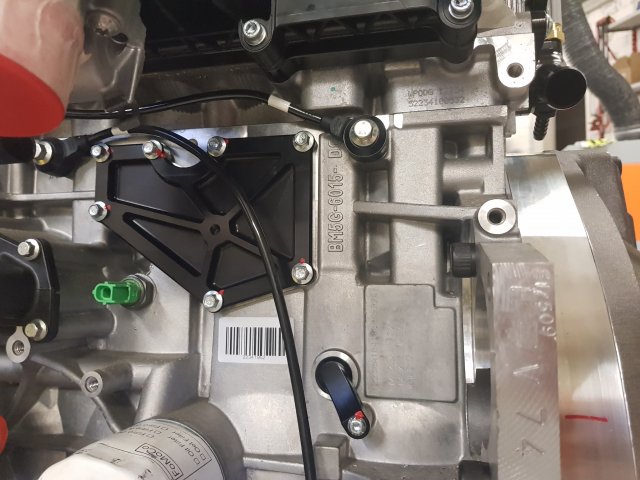

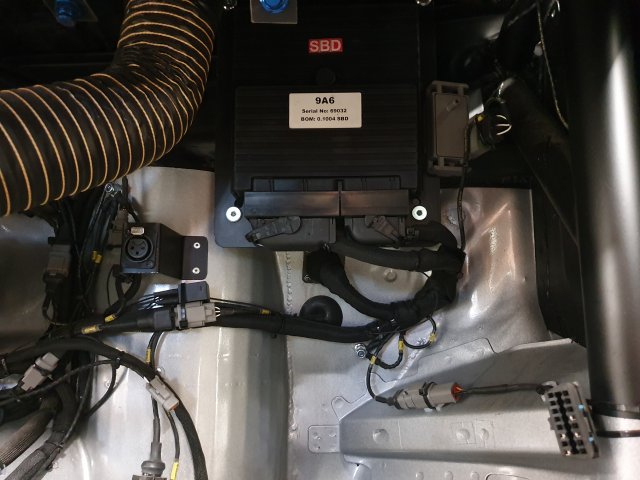

5. Mounting points for custom subframes, engine and transmission.

6. A lot of smaller modifications.

7. Glass blasting.

8. Paintwork.

In every area we were working on, the keyword has been weight. Haven't done it yet, but I am even now thinking of lighter nuts and bolts. The idea of the car is to get the same level of performance as an R5 rallycar, but at half the cost.

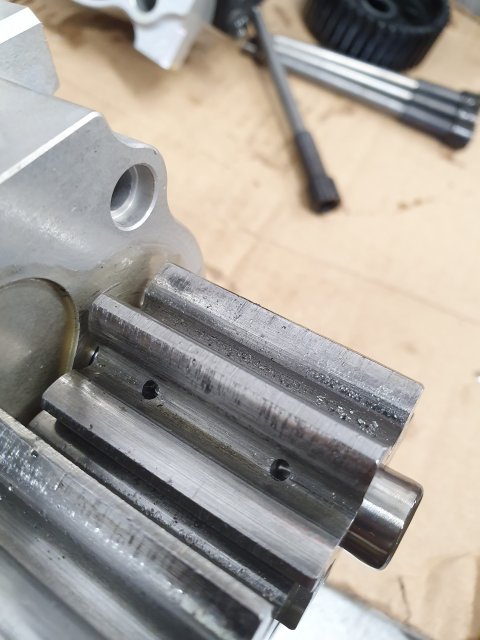

Feel free to throw any questions at me. Will post about the engine and transmission next, with the engine being particularly a roller-coaster ride so far and still a development in progress.

Although I am on the other side of the globe, I found my way here through some searches concerning 1.6 Ecoboost engine builds. Long story short, I am now posting our rallycar build here. The team we are operating is named Kaur Motorsport.

As to this date, the car is only using the engine and the body from ST180- I apologize if that is not enough of ST180 parts to qualify to this forum(or for your personal taste). But it seemed to me it is the best place to find likely-minded people where 1.6 Ecoboost is involved and I could also accumulate more knowledge myself through some discussions.

I will start with the body and what has been done:

1. Completely stripping the body and removing unnecessary components.

2. Modifications to the body to install R5 bodykit and custom suspension. Container for homologated ATL fuel tank.

3. Installing a TIG-welded CrMo rollcage kit with FIA approved homologation. Custom steering column attachments to move seating position towards the rear of the car.

4. New tunnel to accommodate the propshaft.

5. Mounting points for custom subframes, engine and transmission.

6. A lot of smaller modifications.

7. Glass blasting.

8. Paintwork.

In every area we were working on, the keyword has been weight. Haven't done it yet, but I am even now thinking of lighter nuts and bolts. The idea of the car is to get the same level of performance as an R5 rallycar, but at half the cost.

Feel free to throw any questions at me. Will post about the engine and transmission next, with the engine being particularly a roller-coaster ride so far and still a development in progress.

![Cool Smile [coolsmile] [coolsmile]](/images/smilies/cool.png)

![Wink [wink] [wink]](/images/smilies/wink.gif)

![Really Confused [???:)] [???:)]](/images/smilies/confused.gif)